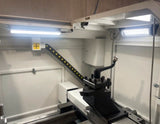

CNC system WT26

Our system was developed specifically for tracing the contours and reworking of aluminum rims.

The rim contour is recorded using a very precise 3D sensor. The contour is then smoothed and perfected using an autoshape program. This means you can achieve very quick and precise processing of a wide range of aluminum rims

Special features/equipment:

- Large 15-inch touchscreen monitor (no laptop needed to read and correct the contour)

- Reliable autoshape of the rim contour, no need to set points on the contour

- Contour rotation is also possible using the contour editor program

- Continuously adjustable cutting and spindle speed

This means that every rotation image can be easily reproduced (coarse to fine)

Perfect for low-base rims, as you can adjust different axles

Cutting area

Rims can be over-twisted more in some areas than in other parts. This means that if there is 2mm of curb damage on the outside, the entire rim does not have to be overtightened by 2mm

Sensing distances freely adjustable (rims that have an interrupted rotating surface can be rotated with a program

- For heavy contours, several points can be set for more precise scanning

- Rotatable button for drop center rims for precise measurement of radii and contours

- Differently directed chisels for any contour

- Rotatable tailstock

3 jaw soft chuck from 14-26*

Automatic oiling of the bed track etc

Completely closed door including door contact switch

Very bright LED for perfect illumination of the work area

Spindle speed 40-1800 g/min